The timing chain system, a long-standing method for connecting the camshaft to the crankshaft and powering essential engine components, is a familiar design in numerous vehicles, notably those from BMW. However, certain engines, particularly the BMW N47, are notorious for timing chain vulnerabilities. This article delves into a real-world case encountered on a BMW E61 520d with 180,000km mileage, where sudden engine failure pointed towards a timing chain issue. This guide, brought to you by eurodripusa.net, your trusted source for All Euro car parts, will walk you through the diagnosis, repair process, and preventative measures related to this common problem.

Diagnosing the Timing Chain Failure in a BMW N47 Engine

The timing chain’s location at the rear of the engine, near the transmission, necessitates engine removal for thorough inspection. In this particular BMW E61 520d case, engine seizure prompted an investigation into potential timing chain failure.

Upon engine removal and rocker cover disassembly, the extent of the damage became apparent. The camshaft chain was displaced at the bottom of the timing chain housing, and critically, five rocker arms were fractured. Further examination revealed a significant fracture in the camshaft support, indicating substantial torsional force impacting the engine timing components. (Fig 1)

Fractured camshaft support and damaged rocker arms due to timing chain failure in a BMW N47 engine.

Fractured camshaft support and damaged rocker arms due to timing chain failure in a BMW N47 engine.

Fig. 1: Significant damage to the camshaft support, highlighting the force of timing chain failure.

With the crankshaft secured, removal of the clutch, flywheel, and sump allowed for further inspection. Removing the timing chain housing exposed additional damage. The upper chain exhibited a broken link, the high-pressure fuel pump sprocket had damaged teeth, and the chain guide was also fractured. (Fig 2)

Broken timing chain link and damaged fuel pump sprocket from a failed BMW N47 engine timing chain.

Broken timing chain link and damaged fuel pump sprocket from a failed BMW N47 engine timing chain.

Fig. 2: Close-up view of the broken upper timing chain and damaged fuel pump sprocket, typical signs of N47 engine timing chain failure.

This scenario is a classic example of timing chain failure in the BMW N47 engine. A comprehensive engine inspection is crucial to identify any secondary damage. In this instance, the intake camshaft was found to be twisted and improperly seated on its bearings, requiring replacement.

Considering the severity of the damage, it was essential to verify if the intake and exhaust valves had collided with the pistons. Cylinder head removal and valve inspection revealed no valve-piston contact, fortunately averting more extensive damage.

Repairing the BMW N47 Timing Chain: A Step-by-Step Guide

After a detailed engine assessment, all damaged components were identified for replacement. When addressing timing chain issues, it is imperative to replace all timing chain components. Neglecting to replace even seemingly minor parts can lead to severe engine problems down the line.

The Febi timing chain kit 102040 is specifically designed for this engine and includes all necessary components for a complete repair. This comprehensive kit contains upper and lower chains, chain guides, tensioners, sprockets for both the fuel injection pump and camshafts, and the essential oil nozzle for the lower chain. You can find this and other quality Febi Bilstein parts for all euro cars at eurodripusa.net.

This Febi kit represents the latest technical advancements aimed at preventing recurrent chain failures. It features an upgraded chain guide design and premium quality chains treated with TRITAN® coating. This specialized coating enhances friction properties, minimizing wear and optimizing engine fuel efficiency.

The cylinder head was prepared for reassembly, incorporating a new camshaft support, camshaft, and rocker arms (Febi 30132). Crucially, the camshaft bracket bolts should be tightened to a maximum of 20Nm, and proper lubrication of camshaft bearings prior to installation is vital. New bolts (Febi 39805) were used when reassembling the cylinder head to the engine block.

Precise Timing and Reassembly

Verifying the camshaft and crankshaft timing is paramount for correct engine operation. The camshaft pinions feature timing marks that must be aligned opposite each other, parallel to the cylinder head. (Fig 3) The crankshaft is locked using a pin in the flywheel, which should be temporarily reinstalled to confirm locking.

Camshaft timing marks aligned for proper engine timing during BMW N47 timing chain replacement.

Camshaft timing marks aligned for proper engine timing during BMW N47 timing chain replacement.

Fig. 3: Correct alignment of camshaft timing marks ensuring accurate engine timing after repair.

The lower chain was installed first, along with the new fuel injection pump sprocket, followed by securing the chain guides with their bolts. The hydraulic tensioner was installed, ensuring clean contact surfaces with the engine block. The lower chain and oil pump sprocket were then fitted, observing the correct installation direction.

Next, the upper chain was installed, connecting the injection pump sprocket to the intake camshaft sprocket. The upper chain guide was then assembled, using thread lock on the bolts to prevent loosening during engine operation.

Once all chains were in place, the locking pin was removed from the hydraulic tensioner of the lower chain. With all chains installed and the flywheel locked, the alignment was checked against the AAC markings on the cylinder head. After confirming correct alignment, the camshaft sprocket was tightened using the three retaining bolts. If misalignment occurs, it can be corrected by adjusting the exhaust camshaft with a 32mm spanner. Finally, the fuel injection pump sprocket tightness was verified.

The assembly of the Febi 102040 timing chain kit was complete. The engine was manually rotated several times to ensure smooth and free movement. (Fig 4) The timing chain housing was reassembled with a new seal, along with a new crankshaft seal.

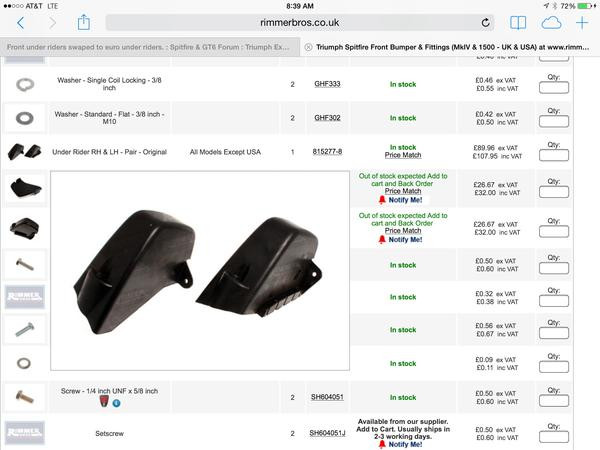

Completed BMW N47 engine timing chain replacement using Febi kit, engine ready for reassembly.

Completed BMW N47 engine timing chain replacement using Febi kit, engine ready for reassembly.

Fig. 4: Engine after successful timing chain kit installation, ready for final reassembly and testing.

Final Steps and Preventative Maintenance for Your Euro Car

With the valve timing correctly set and reassembled, all remaining engine components were reinstalled before returning the engine to the engine compartment. After engine refitting, the oil filter was replaced, and the engine was filled with the correct grade of oil. Regular engine oil and filter changes are critical for the longevity of all euro engine components, particularly the timing chain, which relies on consistent lubrication. Using high-quality oil from trusted brands available at eurodripusa.net can significantly contribute to engine health.

Once the engine was installed and the cooling system refilled with fresh coolant, the engine was started and checked for leaks and proper function. A road test was conducted to evaluate vehicle performance, ensuring it was ready for many more miles of driving enjoyment.

Keep your euro car running smoothly with quality Febi Bilstein engine timing components, available at alleuro.com:

https://alleuro.com/Brands/Febi-Bilstein?SearchIndex=0&Page=0&Category=Engine