Obesity is a growing global concern, prompting the food industry to explore innovative ways to create healthier products. Recent euro news highlights consumer demand for nutritious yet convenient food options, pushing manufacturers to reformulate classic recipes. This article delves into the groundbreaking research on transforming a beloved snack – the muffin – using inulin and green bananas. These natural ingredients are not just trendy; they represent a significant step towards healthier baking, aligning with the latest euro news trends in food and wellness.

The Obesity Challenge and the Call for Food Reformulation

The 20th century’s technological advancements have unfortunately coincided with a surge in obesity rates worldwide [1]. Ultra-processed foods now constitute a significant portion of diets in developed nations [2], contributing to this public health crisis [3]. Transnational food companies are increasingly engaging in product reformulation to address these concerns [4]. However, smaller businesses often lack the resources for extensive research and development in this area [5]. To bridge this gap, comprehensive knowledge bases are being developed to guide food industry players, especially SMEs, through the complexities of reformulation, considering factors like quality, consumer acceptance, nutrition, regulations, and industrial feasibility [6]. This study on muffin reformulation is rooted in these guidelines, aiming to provide practical insights.

Muffins, particularly the American-style sweet variety, are globally popular snacks with a growing market [7]. In the UK, for example, they rank among the most consumed processed snacks [8]. However, traditional muffins are often energy-dense, high in sugar and fat [9]. The rising tide of health awareness and stricter governmental guidelines are pushing manufacturers to improve the nutritional profiles of their offerings to stay competitive and meet public health goals [10,11]. Recent recommendations suggest limiting sugar and energy content in muffins to 27.9 g/100 g and 325 kcal/portion, respectively [12].

The flexibility in muffin recipes, unregulated by strict macronutrient or flavor legislation, makes them ideal candidates for reformulation. However, two key aspects must be considered. First, the “clean-label” trend necessitates using natural alternatives, moving away from artificial additives and high-intensity sweeteners, which are restricted in bakery products within the European Union [13,14,15]. Second, reducing sugar and fat can significantly impact the quality and sensory appeal of muffins. Sugar contributes to bulk, moisture control, shelf life, texture, flavor, color, and gas retention during baking [16,17,18,19]. Fat enhances palatability, reduces crumb firmness, and stabilizes batter aeration [20,21].

Extensive research has explored methods to enhance muffin nutrition by reducing wheat flour, sugar, and fat [16,22,23]. Fiber sources like pecan nut meal [22], waxy whole wheat flour [24], and resistant starch [25] have been used to replace wheat flour. For sugar reduction, options include high-intensity sweeteners (like stevia) [16], polyols [26], and fructans [27]. Fat reduction has been achieved using dietary fibers [28], fruit purees [29], and oleogels [30].

Wheat flour and sugar reduction primarily aim to lower the glycemic index and load [16,31,32], while fat reduction directly decreases energy density due to fat’s higher caloric value (9 kcal/g) compared to carbohydrates and protein (4 kcal/g) [33].

Inulin, a prebiotic dietary fiber (fructan), is composed of fructose molecules linked by β(2-1) bonds, forming oligomers and polymers, often with a glucose molecule at the end [34]. With a degree of polymerization between 2 and 60, and an average of 12 [16], short-chain inulin offers sweetness, high solubility, and low viscosity. This makes it an excellent sugar and fat replacement in various foods without compromising product quality [35]. Found in plants like chicory roots, artichokes, garlic, and green bananas [16], inulin can replace up to 50% of sucrose [16] and fat [21] in muffins, potentially maintaining consumer appeal, manufacturability, and shelf life.

Green banana flour (GBF) is nutritionally rich, containing up to 58.5% resistant starch and 15.5% fiber, along with phenolic acids, including anthocyanins [36]. Its use in the food industry is expanding, utilizing bananas rejected due to minor defects or grading issues [37]. Green banana flour shows promise in reformulation, successfully used in reduced-fat sausages [38] and chicken nuggets [39]. It has also partially replaced cassava starch in crackers [40] and wheat flour in bread [41].

Many muffin reformulation studies use basic recipes, unlike modern industrial production which includes emulsifiers, humectants, and texture enhancers [42,43]. Furthermore, they often lack evaluation of industrial applicability regarding essential product characteristics [23,44]. This study aimed to address these gaps by developing and reformulating an industrial-style muffin recipe, mirroring store-bought muffins’ macronutrient profiles, using inulin and green banana flour as clean-label substitutes for sugar and fat reduction. The research followed the ‘Reformulation Knowledge-Base’ guidelines [6], encompassing recipe development, physical and sensory evaluation, purchase intent, baking losses, nutritional properties (calorie reduction, glycemic impact, hunger perception), shelf life, cost, and industrial process considerations.

Muffin Formulations

Muffin Formulations

Materials and Methods: Crafting Healthier Muffins

Recipe Development: Mimicking Industrial Standards

A control muffin recipe was designed to replicate commercially available, store-branded muffins found in leading UK supermarkets. These typically include wheat flour, sugar, water, eggs, rapeseed oil, humectants (glycerol), starches, whey powder, skimmed milk powder, emulsifiers (soy lecithin, mono- and diglycerides of fatty acids, sodium stearoyl-2-lactylate), raising agents (diphosphates, sodium carbonate, potassium carbonate), acidity regulator (citric acid), salt, stabilizers (xanthan gum, carboxy methyl cellulose), preservative (potassium sorbate), and flavorings. Average sugar content was 22.3 ± 3.5 g/100 g, fat 18.26 ± 2.4 g/100 g, and calorie count around 377 ± 26 kcal/100 g.

The ingredient list for the control muffin in this study is detailed in Table 1, aiming to closely match the properties of packaged muffins.

Ingredients: Choosing Clean-Label Alternatives

Ten muffin formulations were created, reducing sugar and/or fat by varying percentages and replacing them with inulin and/or green banana flour (GBF) (Table 2). Standard baking ingredients were used, sourced from common retailers and suppliers, ensuring readily available components. Organic green banana flour was sourced from Australia, known for its 38% resistant starch and 12% fiber content.

Muffin Formulations: Exploring Reduction Strategies

Sugar and/or fat were substituted with inulin and/or GBF in ten different formulations. Table 2 outlines the specific reductions and substitutions in each formulation, allowing for a comparative analysis of different approaches to sugar and fat reduction using these clean-label ingredients.

Muffin Preparation: A Step-by-Step Industrial Approach

Muffin preparation mirrored industrial baking processes (Table 3). This included creating an emulsification gel and preservative mixture, careful mixing of wet and dry ingredients, and controlled baking and cooling. This standardized method ensured consistency across all formulations, crucial for accurate comparison.

Physical Properties Analysis: Texture and Color Evaluation

Texture Analysis: Firmness and Springiness

A Texture Analyzer was used to measure muffin firmness and springiness. Crusts were removed, and cylindrical crumb samples were compressed to assess textural changes due to reformulation.

Color Measurement: Crust and Crumb Appearance

A portable colorimeter quantified crust and crumb colors using L* (lightness), a* (redness), and b* (yellowness) values. Multiple readings ensured accurate color profiles for each formulation.

Baking Losses: Measuring Moisture Content

Baking losses, crucial for industrial production, were calculated by comparing muffin weights before and after baking. This indicates moisture retention, influenced by ingredient modifications.

Sensory Evaluation: Consumer Perception and Preference

Sensory properties were evaluated by 60 panelists, assessing ‘crumb color’, ‘crust color’, ‘smell’, ‘texture’, ‘softness’, ‘moistness’, ‘swallowability’, ‘taste’, and ‘overall acceptability’ using a 5-point hedonic scale. Purchase intent and price willingness were also surveyed to gauge consumer acceptance of reformulated muffins.

Nutritional Properties: Energy, Glycemic Response, and Hunger

Energy Content Calculation

Energy content was calculated using the Atwater factor system, considering the calorie values of each ingredient, including inulin and GBF, to determine calorie reduction in reformulated muffins.

Glycemic Response Study: In-Vivo Testing

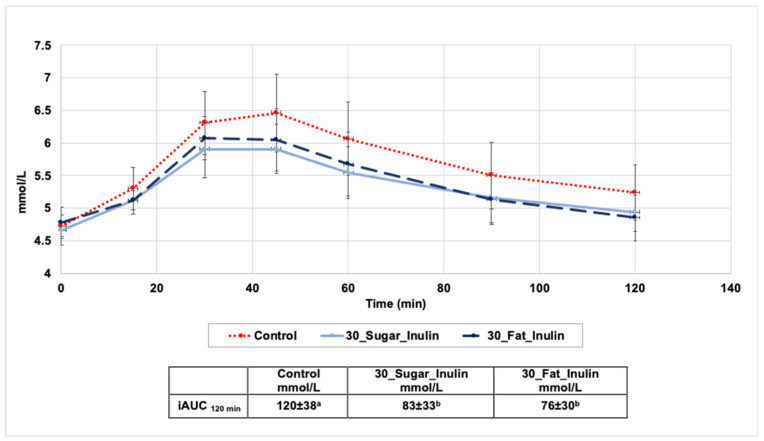

A randomized, controlled, crossover study with 15 healthy adults evaluated the glycemic response to control, 30% sugar-reduced (inulin), and 30% fat-reduced (inulin) muffins. Blood glucose levels were monitored for 120 minutes post-consumption.

Hunger Perception Assessment

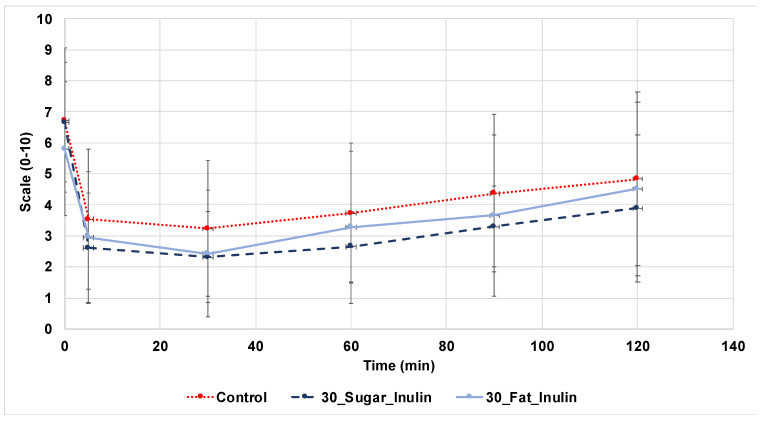

Subjective hunger levels were recorded using a 10 cm visual scale at various intervals during the glycemic response study to assess the satiety effect of reformulated muffins.

Shelf-Life Study: Microbial Stability

Microbial shelf life was assessed for control, 30% sugar-reduced (inulin), and 30% fat-reduced (inulin) muffins over 10 days at 25 °C. Total viable counts and yeast/mold growth were monitored to determine the impact of reformulation on microbial stability.

Statistical Analysis: Data Interpretation

ANOVA and Post-Hoc tests were used for texture and sensory data. Repeated measures ANOVA analyzed glycemic response and hunger data, determining statistical significance of reformulation effects.

Results and Discussion: Unveiling the Impact of Reformulation

Texture Properties: Firmness and Springiness

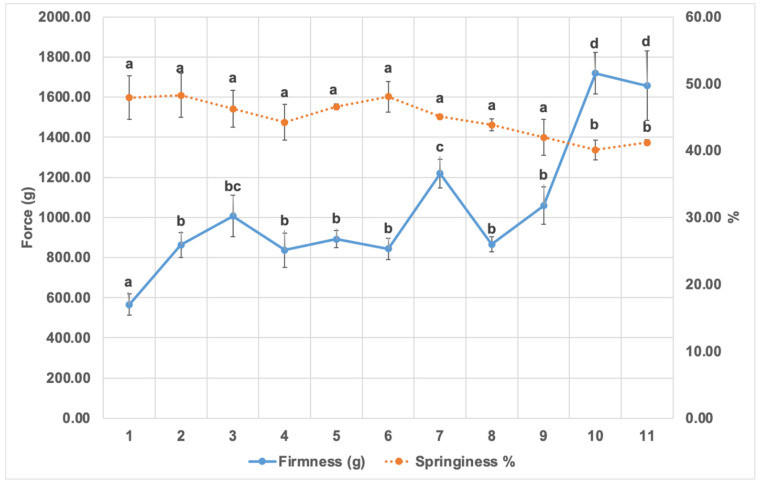

Texture analysis revealed that reformulated muffins, particularly those with reduced sugar and/or fat, were significantly firmer than control muffins (p < 0.05) (Figure 1). This aligns with previous studies showing that fiber addition increases firmness [21,43]. Fibers’ high water-binding capacity reduces water availability for starch, affecting texture [51]. Inulin‘s impact on firmness varies with concentration, with higher replacement levels leading to increased firmness [16].

Springiness remained largely unaffected by sugar/fat reduction, except in samples with 30% reduction in both sugar and fat (30_Sugar_Inulin_30_Fat_Inulin and 30_Sugar_Inulin_30_Fat_GBF), where it decreased, indicating a denser crumb. This is consistent with findings that high fiber content can reduce springiness [27,34,52]. Sugar and fat contribute to softer, springier textures by influencing starch gelatinization and protein denaturation, and by stabilizing air bubbles, respectively [16,34,53,54].

Muffin Firmness and Springiness

Muffin Firmness and Springiness

Color Analysis: Crust and Crumb Appearance

Color parameters (Table 4) showed that inulin substitution did not significantly alter crust and crumb color compared to control muffins. Similarly, 10% GBF formulations maintained control-like color. However, 30% GBF fat substitution resulted in darker crusts, with lower yellowness (b*) and lightness (L*) but higher redness (a*) values (p < 0.05). This color change with GBF is expected due to its inherent color, as observed in other studies [21,25,55].

Baking Losses: Moisture Retention

Baking losses ranged from 7.31% to 9.14% across formulations (Table 5), likely due to texture enhancers like lecithin, xanthan gum, and glycerine. Muffins with higher fiber content exhibited lower baking losses (p < 0.05), attributed to fibers’ water-binding capacity [55]. Increased moisture retention in fiber-enriched baked goods has been previously reported [56].

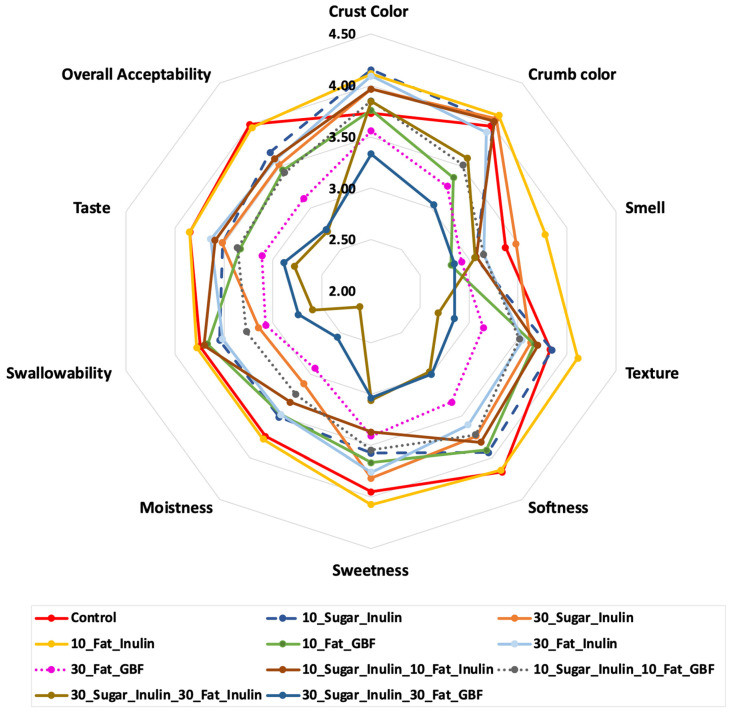

Sensory Properties and Consumer Preference

Sensory evaluation (Figure 2) indicated no significant difference in crust color preference between reformulated and control muffins. However, crumb color scores were lower for GBF-containing samples (10_Fat_GBF, 30_Fat_GBF, 30_Sugar_Inulin_30_Fat_GBF) due to GBF‘s darker color (Figure 3). Smell showed no significant differences. Texture and softness scores were lower in 30% GBF samples and those with highest fiber content (30_Sugar_Inulin_30_Fat_Inulin, 30_Sugar_Inulin_30_Fat_GBF) due to increased firmness. Sweetness was not significantly affected by sugar reduction at 10% or 30% with inulin, or in combined sugar and fat reduction at 10%, suggesting commercial muffins might contain excessive sugar. Moistness, swallowability, taste, and overall acceptability remained comparable to control, even with 30% sugar or fat reduction using inulin. Slight decreases in these attributes were observed in 30_Fat_GBF, 30_Sugar_Inulin_30_Fat_Inulin, and 30_Sugar_Inulin_30_Fat_GBF (p < 0.05), possibly due to texture changes and GBF‘s flavor [34].

Sensory Properties of Muffins

Sensory Properties of Muffins

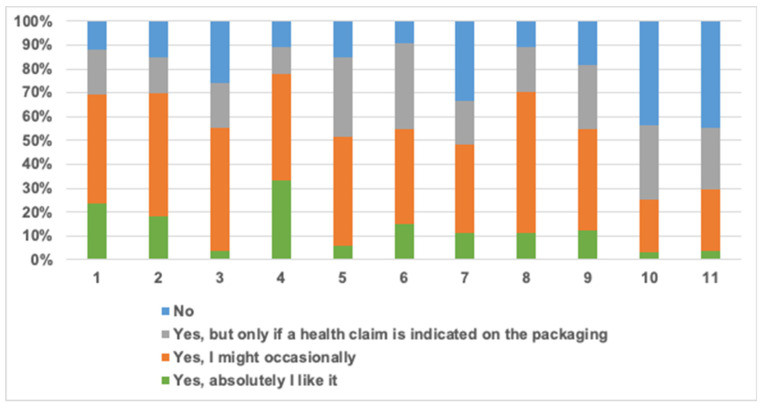

Purchase Intent and Pricing

Purchase intent (Figure 4) was high across all formulations, ranging from 55.6% to 90.9%. 10_Fat_Inulin and control muffins received the highest “Yes, absolutely I like it” responses (33.3% and 27.7%, respectively). 30% sugar-reduced muffins (inulin) had a 74.1% positive purchase intent. 30_Fat_Inulin showed the highest total positive intent (90.9%), surpassing control (88.1%). Formulations with highest fiber content and lower sensory scores had higher “No” purchase intent responses (30_Sugar_Inulin_30_Fat_Inulin and 30_Sugar_Inulin_30_Fat_GBF). Inulin as a fat replacer was generally preferred over GBF, possibly due to color and sweetness differences, which could be mitigated with flavorings like cocoa or fruit.

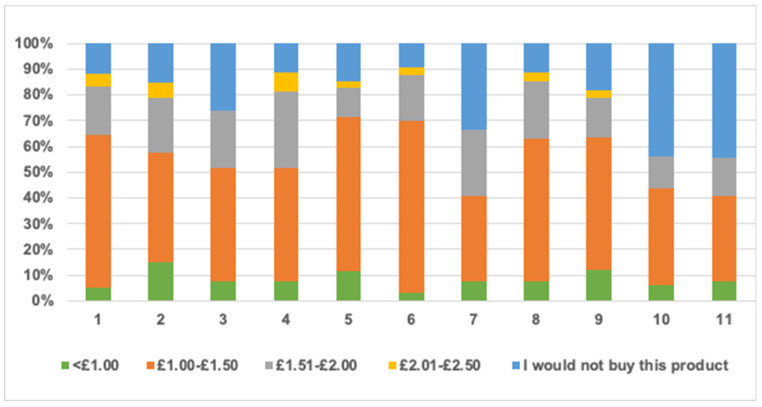

Price willingness (Figure 5) indicated a preference for the £1.00–£1.50 range for all formulations. Participants valued 10% sugar/fat reduction formulations higher than 30% reduction versions.

Consumer Price Willingness

Consumer Price Willingness

Nutritional Benefits and Marketing Claims

Calorie Reduction and Labeling Opportunities

Theoretical energy content (Table 6) decreased by 1.02% and 3.06% with 10% and 30% sugar reduction using inulin, respectively. 30_Sugar_Inulin qualifies for “Reduced sugar—High in fiber” labeling in the European Union [57]. Fat reduction resulted in more significant energy decreases (7.36% and 9.08% in 30_Fat_GBF and 30_Fat_Inulin), enabling “Reduced fat—A source of fiber” claims. 10_Sugar_Inulin_10_Fat_GBF and 10_Sugar_Inulin_10_Fat_Inulin can be labeled “A source of fiber.” The highest calorie reduction (10.42% and 12.14%) was in 30_Sugar_Inulin_30_Fat_GBF and 30_Sugar_Inulin_30_Fat_Inulin, allowing “Reduced sugar—Reduced fat—High in fiber” claims.

Traffic light labeling shifted sugar from red to amber in reduced-sugar muffins, while fat remained amber across all formulations [58].

Glycemic Response: Lower Blood Glucose Impact

Glycemic response testing of 30_Sugar_Inulin and 30_Fat_Inulin compared to control showed significantly lower glucose iAUC (Figure 6) in reformulated muffins (F:1-12 = 129, p < 0.05). Inulin‘s soluble fiber content likely contributes to this reduction by slowing glucose absorption [[59](#B59-foods-10-01883],60]. Studies on inulin‘s impact on glycemic index in pasta and bread support these findings [61,62,63]. 30_Sugar_Inulin and 30_Fat_Inulin reduced peak blood glucose at 120 minutes by 14% and 16%, respectively.

Blood Glucose Response

Blood Glucose Response

Hunger Perception: Increased Satiety Trend

Hunger perception data (Figure 7) suggested a higher satiety effect for 30_Sugar_Inulin and 30_Fat_Inulin, with decreased iAUC120 min, though not statistically significant. This trend aligns with the known satiety-enhancing effects of viscous fibers, although inulin‘s solubility and low viscosity may lead to inconsistent satiety results [64]. Some studies show inulin-rich diets increase satiety and reduce hunger and cravings [66,67].

Hunger Perception Score

Hunger Perception Score

Shelf-Life: Microbial Stability Maintained

Microbial shelf life (Table 8) of control, 30_Sugar_Inulin, and 30_Fat_Inulin muffins remained stable for 10 days at 25 °C. Yeast and mold growth were below detection limits due to potassium sorbate [68]. Total viable counts remained low and comparable across formulations, indicating inulin did not negatively impact shelf life.

Industrial Scale-Up and Cost Considerations

Cost Implications of Reformulation

Reformulation with inulin and GBF increased raw material costs (Table 9). 10% reduction formulations remained within the preferred £1.00–£1.50 price range, while 30% reduction formulations slightly exceeded it. 30% sugar and fat reduction formulations reached £2.00–£2.02. These cost increases are based on retail prices and may be lower for bulk industrial purchases.

Industrial Feasibility and Processing

Inulin and GBF are clean-label, plant-based ingredients suitable for industrial muffin production. European regulations do not restrict their use in muffins. Inulin doses in this study were within acceptable daily intake limits [75].

Industrial scale-up requires identifying large-scale suppliers and ensuring quality control. Increased batter viscosity due to fibers [43] might necessitate adjustments in mixing and pumping equipment, potentially adding to production costs. However, companies prioritizing nutritional improvement can gain consumer trust and market advantage [4,76].

Conclusion: Paving the Way for Healthier Snack Options

This research successfully developed and evaluated reformulated muffins with reduced sugar and fat using inulin and green banana flour. The study demonstrated the feasibility of creating healthier, industrially viable muffins with enhanced nutritional profiles while maintaining consumer appeal.

Key findings include:

- Inulin and GBF can effectively reduce sugar and fat in muffins.

- Sensory acceptance of reformulated muffins was largely comparable to control, especially at 10% and 30% reduction with inulin.

- Purchase intent remained high for most reformulated options.

- Inulin-reformulated muffins showed a significant reduction in glycemic response.

- Shelf life was not negatively affected by reformulation.

While 30% GBF formulations had slightly lower sensory scores, this could be improved with flavor adjustments. Overall, this study indicates the potential for industrial production of reduced sugar or fat muffins using inulin up to 30%, and GBF up to 30% for fat reduction, especially when combined with flavor enhancements to address color changes. These findings offer valuable insights for the food industry seeking to meet consumer demand for healthier and more nutritious snack options, aligning with the growing global focus on health and well-being highlighted in euro news and beyond.

Acknowledgments

The authors gratefully acknowledge the contributions of all volunteers and Praveenkumar Kaveri for facility access at Loughborough University.

Author Contributions

Conceptualization, R.H.; Data curation, R.H.; Formal analysis, R.H. and E.W.; Funding acquisition, E.W.; Investigation R.H., L.J.J. and E.W.; Methodology, R.H.; Project administration, E.W.; Resources, R.H., L.J.J. and E.W.; Supervision, E.W. and L.J.J.; Validation, R.H.; Visualization, R.H.; Roles/writing—Original draft, R.H.; Writing—Review and editing, R.H., L.J.J., S.G., A.J.R. and E.W. All authors have reviewed and approved the final manuscript.

Funding

This research was supported by the EPSRC Centre for Innovative Manufacturing in Food [grant number EP/K030957/1].

Institutional Review Board Statement

The study was conducted ethically, adhering to the Declaration of Helsinki guidelines, and approved by the Loughborough University Ethics Sub-Committee R19-P118 and R19-P119 (September 2019).

Informed Consent Statement

Informed consent was obtained from all participants involved in this study.

Conflicts of Interest

The authors declare no conflicts of interest.

Footnotes

Publisher’s Note: MDPI remains neutral regarding jurisdictional claims in published maps and institutional affiliations.

References

[1] Reference 1

[2] Reference 2

[3] Reference 3

[4] Reference 4

[5] Reference 5

[6] Reference 6

[7] Reference 7

[8] Reference 8

[9] Reference 9

[10] Reference 10

[11] Reference 11

[12] Reference 12

[13] Reference 13

[14] Reference 14

[15] Reference 15

[16] Reference 16

[17] Reference 17

[18] Reference 18

[19] Reference 19

[20] Reference 20

[21] Reference 21

[22] Reference 22

[23] Reference 23

[24] Reference 24

[25] Reference 25

[26] Reference 26

[27] Reference 27

[28] Reference 28

[29] Reference 29

[30] Reference 30

[31] Reference 31

[32] Reference 32

[33] Reference 33

[34] Reference 34

[35] Reference 35

[36] Reference 36

[37] Reference 37

[38] Reference 38

[39] Reference 39

[40] Reference 40

[41] Reference 41

[42] Reference 42

[43] Reference 43

[44] Reference 44

[45] Reference 45

[46] Reference 46

[47] Reference 47

[48] Reference 48

[49] Reference 49

[50] Reference 50

[51] Reference 51

[52] Reference 52

[53] Reference 53

[54] Reference 54

[55] Reference 55

[56] Reference 56

[57] Reference 57

[58] Reference 58

[59] Reference 59

[60] Reference 60

[61] Reference 61

[62] Reference 62

[63] Reference 63

[64] Reference 64

[65] Reference 65

[66] Reference 66

[67] Reference 67

[68] Reference 68

[69] Reference 69

[70] Reference 70

[71] Reference 71

[72] Reference 72

[73] Reference 73

[74] Reference 74

[75] Reference 75

[76] Reference 76